(Update: tractors, fire trucks, busses and airplanes were also shipped in boxcars.)

|

| William Brown posted |

Long before the invention of autoracks the traditional way to move automobiles was via the boxcar, as seen here with new 1938 Buick's. Colorization by Imbued with Hues. From a Facebook Photography Page.Evidently the driver is just steering because they don't trust him to be able to drive the car slowly enough as they watch the spacing between the car and the boxcar's door edge. Considering even the pusher in the back is watching the spacing, it is obviously a tight fit and a slow loading.

I noticed the car is labeled "AUTO RACK". Fortunately a comment explained why they are special.

J Pete Hedgpeth These cars were known as "Evans Auto Cars"...or alternately "Evans device cars. Inside the car was a series of chain hoists and racks so that the autos at the end of the car could be raised up and another auto parked partially underneath the front of the car which was raised up IIRC you could load 6 automobiles in one of these cars.. As you might expect when a chain broke or became unhooked the results were not pretty. In later years after the automobiles by rail business ended...going to trucks...and then back to rail via tri level cars. these Evans cars were used for handling "high cube" low density commodities....Example corn cobs moving to a plant where they were used to produce alcohol.

Jeff Aley Technically, there were other makers of the interior racks besides Evans. But I'm not surprised that people called them "Evans Auto Cars" anyways. The horizontal white stripe on the door indicates that the car has automobile-loading racks.

Brian Patterson The Illinois Railway Museum has preserved CRI&P 264070, a 1930 wood outside-braced automobile car built by Standard Steel.

That gives me an excuse to go to IRM to try to find that car.

|

| Daniel C Carroll Jr. shared Robbie Robertson's photo Steve Lucas The white stripe on the doors indicated that the boxcar was fitted with an Evans Auto-Loader, which allowed four automobiles in it, two above the other two. Interesting to see how dollies were used on the back wheels to get the auto in. Daniel Gless Until the auto carrier multi deck cars were developed in the late 50's/early 60's this is the way it was done...and not done very much. Good articles in last summers Classic Trains about them. |

|

| Imbued with Hues posted 1935 Packard being loaded onto a boxcar for shipment. Packard Motor Car Co., first 120 models on loading dock, awaiting transport by special boxcar to Memphis, in doorway 1935 Packard one-twenty, twelfth series, model 120, 8-cylinder, 110-horsepower, 120-inch wheelbase, 5-person sedan (body type #893). Clare Gilbert Evans Auto Loader in use. The first car was run onto a set of ramps that was then winched up towards the roof. The second car was then tugged, pushed and pulled onto the deck of the box car. The process was repeated at the opposite end of the car to get a total of four autos loaded. Very time consuming and labour intensive. A far cry from the multi level auto racks used by railways now. John Peters My Dad loaded military vehicles in boxcars in 1942 at the Lincoln plant in Detroit until he was called to basic training. I showed him a photo similar to this one once, he said it was “like wrestling with an alligator” to get the last vehicle in. |

This was almost as awkward.

Mary Stahl posted four photos with the comment:

Matthew's comment: "CP open-autorack at Agincourt, Ontario. July, 1964."

Most of the CRO comments talked about the need to add covers because of vandals. But a comment worth noting is the picture is by Jim Parker.

I read that the original reason why covers were put on the sides was that the cars were getting dinged by rocks. I think the rocks were being thrown by kids. Now they are completely covered, including the ends, to keep vandals out. I remember reading the Train's article on vehicle racks that the CD-player was one of the things that disappeared.

Traditionally, railroads build the rack on a TTX flat car. That is, the railroads own the rack and TTX owns the flatcar. Scroll down in IHB to see some older racks I caught in a train. When I visited Dolton Junction, two of the trains I saw go by while I was there were vehicle unit trains. And I saw another vehicle unit train when I visited the Blue Island Junction. Between the two trains, I think I caught all of the Class I railroads in North America (including two Mexico railroads). On closer examination, all of the KCS cars were Kansas City Southern de Mexico so I missed KCS itself.

This is the loading dock for the Ford Assembly Plant in South Chicago. The Trains article said that they are loaded five cars at a time. But I see they have some cuts with six cars. This is serviced by Norfolk Southern's former NKP route.

Three types of CSX logos.

Note this Canadian National car has two yellow columns. I believe that means it is of a newer design that allows the number of levels to be changed between three and two. Cars can use three tiers. But trucks, minivans, and many SUVs can only use two tiers. As oil prices changed, the ratio of cars to the other types would change and the railroads would have too many of one type and not enough of the other type. So a design was developed so the number of tiers in the car could be changed as the market conditions changed.

This is another new design. Note that it is articulated --- both units share the truck in the middle. This means that it counts as just one car as far as billing is concerned. I have noticed that this design evidently was not popular because I have not seen a lot of them.

This is one of those postingx that has a wealth of information in the comments.

Joseph Tuch Santucci And it’s why they are not shipped with the radios in them today. Even covered they are sometimes still broken into. The keys are no longer shipped with the cars either. They are sent separately by FedEx.

Wayne Hudak Thanks for the update. I often wondered about the keys.

Joseph Tuch Santucci Wayne Hudak for a time they put them in the ash trays. Then the put them all into an envelope and hid them in or on one of the cars. In the 80’s they stared send the keys separately. Today they have the airbags disconnected. Those are hooked up at the dealerships.

Don Murray posted four photos with the comment: "I do not know where this is, They look like 1971 Chevy trucks."

Dennis DeBruler shared with the comment: "A testament to the strength of a good chaining job."

Mike Budde I wonder if these were coming from Janesville. Someone on another group said this location was Alma, IL on the IC, from the name on the water tower. As others have mentioned, what an excellent job those guys did tying these trucks down to the train cars.

I wonder if these were coming from Janesville. Someone on another group said this location was Alma, IL on the IC, from the name on the water tower. As others have mentioned, what an excellent job those guys did tying these trucks down to the train cars.

Greg Bunce posted two photos with the comment: "Here's a couple of builders photos of GTW Automobile boxcars built by American Car and Foundry in 1921. Photos from the John W. Barriger Railroad Library."

Eric S. Huffstutler posted four photos with the comment:

Craig Nicol I remember the original batteries for those cars had their cell caps at one edge of the battery so they wouldn't spill in transit. All the underhood reservoirs too.

Eric S. Huffstutler They made over 2-million of these cars between 1971-1977. Pinto was produced 3 years longer 1971-1980 and produced just over 3-million.

Emery Flatt The Ford Pinto was shipped the same way. [This comment was evidently wrong. But as proof that he was correct, he posts a photo of a standard covered autorack. And yet later in the comments he delights in pointing out someone's typo. He has more comments, and I think I now understand what an internet group "know it all" is.]

Todd Allen Typically new cars are filled with fluids for testing, then drained for shipping. They still do this today.

Steve Dolan I know from personal experience, Toyotas are shipped via rail with all fluids. They even start them and drive them off the rail car. Watched them unload many of them at Southeast Toyota Distributors.

Al Carpenter Ed Cole's folly. GMAD Lordestown could build 100 unit per hour. Sales were far less brisk. The freedom battery was perfected, true, but rural offloading occasionally involved guiding a fork lift arm through open windows to keep rail schedules. Repairs were extensive.

Eric S. Huffstutler More info... Vega’s engineers had to design a special engine oil baffle to prevent oil from entering the No. 1 cylinder of the car’s inline-four engine. Batteries had filler caps located high up on the rear edge of the case to prevent acid spills. The carburetor float bowl had a special tube that drained gasoline into the vapor canister during shipment, and the windshield washer bottle stood at a 45 degree angle. Plastic spacers were wedged between the powertrain and chassis to prevent damage to engine and transmission mounts. The wedges were removed when cars were unloaded.

John Levy I was there. Trust me, there was a high demand for this car, along with the Pinto. In 1974, they sold over 460,000 Vegas. There were a lot of very good features on the car, but it was also woefully inadequate in many ways. I had a brand new 73 and it drove and handled very well. Obviously there aren't many left because of the dreadful rust prevention on the car. The original aluminum block engine was poorly designed. The interior was very nice and dang it was rear wheel drive. Can you imagine a bargain priced rear wheel drive car in today's market?

George Bishopric Though the Vega’s die-cast aluminum engine had undergone some 6 million miles of development testing, serious reliability issues surfaced soon after the car’s release. A six-quart cooling system and small radiator proved barely sufficient to prevent overheating in warmer climates, and the aluminum engine block soon earned a reputation for distorting when hot. This frequently led to the piston rings scraping the silica used to harden cylinder walls, increasing oil consumption (though to be fair, valve stem seals were also a known source of oil consumption). In extreme overheating, the engine block’s distortion could be severe enough to compromise the head gasket, leading to coolant leaks and further destructive overheating.

Chevrolet took until 1976 to resolve issues with the Vega’s 2.3-liter four-cylinder engine, and by then even a serious marketing effort to promote the new “Dura-Built 140” engine proved to be too little, too late. The new engine improved coolant flow through the block; used a revised head gasket and water pump; added revised valve guide seals; and changed the thermostat, but not even an increased five-year, 60,000-mile warranty was enough to restore consumer confidence. Sales in 1975 totaled just more than 206,000 units, and fell even further, to less than 161,000 units, following the release of the Dura-Built 140 engine in 1976. In 1977, the Vega’s final year of production, only 78,402 models found their way into consumer driveways.

George Bishopric I bought one when I was 18. The things I liked about it then, I still like about it.

For its time, it was a relatively comfortable small car. It handled very well, and until it began to fall apart, it was quite competitive with other small cars which you must remember we were remarkably more tinny, noisy and cramped than any small car today

The car had a appalling quality, however. The plastics used in the interior would be rejected for Walmart for use in a dishwashing rack. The carpet was basically lint, pulled from an industrial clothes dryer. The inner fenders were deleted to save money, along with a glove box

The cars began rusting, almost before they left the show room. My windshield and rear window had to be removed for rust repair within six months of purchase. The tires had to be replaced at 16,000 miles. Back in the day, that was outrageous, and these were not high-performance tires by any stretch.

George Bishopric The motor's issues were best symbolized by the oil filler cap: Basically, a rubber bottle stopper, that could only be removed with difficulty, which was a problem in such an oil thirsty motor. My engine blew a head gasket at 18,000 miles on a cool Sunday morning. By the time I traded the car in, it could not go more than 40 mph with passengers in it.

Todd Allen I remember taking a head off one of these Vegas- the bolt was so seized I used a water pipe for a hot water heater pressure relief valve drain over the rachet (about a 4 foot leverage arm) and broke two sockets with two guys working on it. Had to buy an industrial grade impact socket before that sucker woud budge and my 4 foot breaker bar.. Blown head gasket of course.

George Bishopric Patrick Mullen GM basically handed the small car market to Toyota at that point. Had GM gone with the "premium small car" concept, and not slashed quality to meet unrealistic price targets, they would have met the challenge of import competition. A massive unforced error.

George Bishopric "Contrary to popular belief, GM did rust proof the cars, but its design allowed for air pockets to develop between the front fenders, cowl, and firewall during the rustproofing process, leaving the steel in those areas dangerously unprotected. Yet while all these defects were known to company brass, the Vega debuted on September 10, 1970, and just like GM hoped...." http://www.cheatsheet.com/.../why-the-chevy-vega-set.../...

There is a wealth of information about autos in boxcars in the comments for this posting. (I verified with an Incognito Window that you don't have to be a member of the group to read the comments, but you do have to be a member of Facebook.)

The following information came from the comments by Bob Lalich and others on a post asking about this facility with a figure-8 track. Note that the "X" of the "8" appears to be grade separated. According to topo maps, it was built between 1929 and this 1938 aerial photo. My current theory is that the track was used for accelerated testing of the trucks turning in a new, possibly interurban, car design.

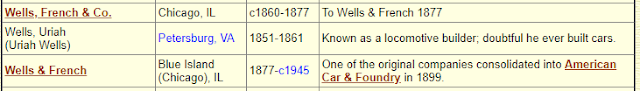

Bob Lalich It was Evans in later years. Before that I think it was US Railway Equipment, and possibly Wells & French before that.

The figure-8 part looks like a scrap yard and the eastern part is now the IAIS railyard.

Information from https://www.midcontinent.org/rollingstock/list/listhome.htm doesn't include the change from US Railway Equipment Manufacturing to Evans nor that French & Wells was the precursor to US Railway.

Wells & French: https://www.midcontinent.org/rollingstock/builders/Wells-French.htm

Paul Musselman commented that a Google search with the keywords: "Evans automobile boxcars" offers several photos. Looking at the photo results, Kalmbach covers this topic in their Railroading & The Automobile Industry book. And core77 has four photos from LIFE on the subject.

Jimi Krentkowski I wish this picture was more clear. I was looking at an old Trains magazine, perhaps 1988, and it was on the Iowa Interstate. They used the old Evans car plant as their switching yard. They had an aerial view which is a lot different than today. It looks like to figure 8 race track! Lol) Is now a scrapyard. And the Rock island tracks over the old b&o / harbor belt bridge was replaced bout 1945-47ish. This is a very cool picture for sure. Thanks for posting this Daniel.

Bob Lalich Daniel O'Hearn - that thread from Trains discussion forum has a good tidbit of info. The Blue Island site was once the Mather Stock Car Co, which was merged into North American Car Co. at some point. The 1956 directory of industries lists a site for North American at 135th St in Blue Island.

Dwayne Weber posted two photos with the comment: "Found some info on something NYC either explored or declined. Anything out there about the possible color of the flat or carrier?"

Kim Powell Guess there was a prototype for Lionel's#6414 Evans auto loader.

[Evans evidently developed this design as a transition to the autoracks we see today.]

Richard Roberts shared

Greg Worobey I had a Lionel flat was black and carrier red.

Stuart Thomson I have the original press release book from Evans but it is in black and white. I am sure the flat was black. Not sure on the rack. Evans paid for the Lionel tooling. Evans designed the rack to permit end loading or side loading off to a dock. Unfortunately they never tried using a PRR 75' flat car or the new 85' trailer flat car. to load more cars. Problem was autos at that time were very high and a tri-level was not possible, thus not enough revenue. Plus the rack was very heavy and expensive. However in 1960, auto companies introduced unit body construction which lowered the car height by about a foot. Then Frisco and ATSF could make tri-levels for their high clearances. In 1961 the eastern railroads introduced elevator racks that lowered the overall height by 2'. It took three more years to open up clearances in the east for standard tri-levels with fixed decks ( the "B" deck was hinged at the ends ) on low level flats that also had EOC couplers. Those elevator racks only lasted five years and were scrapped or rebuilt.

Stuart Thomson That superstructure with the chain drive to raise and lower decks really added to the cost plus having the heavy bridge construction to permit side loading also added cost to the rack. Too bad the concept of just end loading of autos was still five years away. Also at the time box cars with autos would go to area sidings nearest the dealer and off load. Sometimes the box car would make two stops. Unlike shipping cars to a huge off load yard of today.

Another transition solution.

Jason Boche shared : a video of the top of some autoracks being "scraped off."

the majority of this video is the second shove move. There must have been an initial shove move that did that damage and it went undetected.

|

| Mark Hershoren posted 1937 (or there-abouts) Studebaker coupe bodies being loaded in a boxcar. |

|

| Walter Hooker posted Edward Jarolin shared |

Mary Stahl posted four photos with the comment:

Frisco developed the tri-level auto hauler with Chrysler to serve their plant in Fenton, MO. This one was donated to our MOT. Frisco gave employees a poster of one of the unit trains leaving the plant and back of poster showed cars being loaded. We saved Dad's copy.

|

| 1 |

|

| 2 |

|

| 3, cropped |

|

| 4, -100+50, unfortunately, I could not make it readable. |

|

| Matthew Frederick shared CRO's photo |

Most of the CRO comments talked about the need to add covers because of vandals. But a comment worth noting is the picture is by Jim Parker.

I read that the original reason why covers were put on the sides was that the cars were getting dinged by rocks. I think the rocks were being thrown by kids. Now they are completely covered, including the ends, to keep vandals out. I remember reading the Train's article on vehicle racks that the CD-player was one of the things that disappeared.

Traditionally, railroads build the rack on a TTX flat car. That is, the railroads own the rack and TTX owns the flatcar. Scroll down in IHB to see some older racks I caught in a train. When I visited Dolton Junction, two of the trains I saw go by while I was there were vehicle unit trains. And I saw another vehicle unit train when I visited the Blue Island Junction. Between the two trains, I think I caught all of the Class I railroads in North America (including two Mexico railroads). On closer examination, all of the KCS cars were Kansas City Southern de Mexico so I missed KCS itself.

|

| Satellite |

|

| Ferromex |

|

| Conrail |

|

| Southern Pacific |

Three types of CSX logos.

Note this Canadian National car has two yellow columns. I believe that means it is of a newer design that allows the number of levels to be changed between three and two. Cars can use three tiers. But trucks, minivans, and many SUVs can only use two tiers. As oil prices changed, the ratio of cars to the other types would change and the railroads would have too many of one type and not enough of the other type. So a design was developed so the number of tiers in the car could be changed as the market conditions changed.

|

| Norfolk Southern |

|

| Kansas City Southern de Mexico |

|

| BNSF |

|

| An older Canadian National design |

|

| I see TTX will also make the rack as well |

|

| The original BNSF logo before the company changed its name to BNSF. |

|

| Canadian Pacific Note the rest of these pictures were from the westbound UP that is coming. |

|

| Another KCSdM |

|

| CP Rail |

|

| KCSdM |

This is another new design. Note that it is articulated --- both units share the truck in the middle. This means that it counts as just one car as far as billing is concerned. I have noticed that this design evidently was not popular because I have not seen a lot of them.

|

| The westbound had a DPU |

|

| William A. Shaffer posted "Auto Racks at Decatur, IL" (Photo by William A. Shaffer) Mark E. Vaughan Later the op department issued instructions to place "spacer cars" between the locomotives and the open auto racks as the diesel exhaust left a hard-to-remove film on the autos on the top level. The N&W hated to pay for damage claims and repairs. Sammy Smith I believe it. When I worked for the KCS, I had a white Impala company station wagon. I had to use the same steam cleaner and chemicals they used to wash locomotives now and then. |

|

| Canada AutoNews |

|

| Dennis DeBruler shared Chuck Hart's photo. This is a picture I took of a picture I saw in an antique store. The picture was priced at $55 so I passed on it. I may go back and buy it if still available. Anyone else seen or have a picture of an auto carrier on a flat car? |

|

| Dennis DeBruler shared William A. Shaffer's post. A southbound N&W Freight Train passes Millikin University. Two railroaders are enjoying the view from the rear platform of the Caboose---a scene that is no longer repeated! (Photo by William A. Shaffer) [Having a caboose means the picture is old. But I believe having open autoracks makes it even older. Rail clearance was probably not an issue for open cars.. The reason the upper corners of a covered car are curved is to increase the number of tunnels they can go through. If you look at the notches they are now putting into some tunnels for double-stacks, the curves make a big difference in the east in terms of route choice.] |

|

| Dennis DeBruler shared Illinois Central Railroad Scrapbook's post A couple days I posted a mystery photo of an IC auto racks/auto parts train rounding a curve on March 21, 1970, and asked where it was taken. Several folks correctly replied "Thebes, IL". Unfortunately there is no prize for giving the correct answer. The train in question was a test train for General Motors. Auto parts and fully assembled cars from GM plants in Michigan were shipped by PC, Grand Trunk, and C&O and delivered to IC's Markham Yard in Homewood, IL. At Markham Yard the cars were assembled into a single train and dispatched south over the IC to East St. Louis. The train was handed over to the Cotton Belt and then to the SP for final delivery to GM plants and dealerships on the West Coast. An unknown IC company photographer caught the train as it charged around the curve leading to the Mississippi River bridge at Thebes, IL. The photographer also caught a going away shot of the train, included here. BTW, many fans are familiar with the MoPac's and Cotton Belt's "Joint Line" operations across the Thebes bridge, and that in recent years MoPac owned 60% of the bridge, and Cotton Belt owned 40%. The Thebes Bridge was built by the Southern Illinois & Missouri Bridge Company. When the company was formed, the SI&MBCo. was owned equally by the Cotton Belt, Chicago & Eastern Illinois Railway, the MIssouri Pacific Railway, the St. Louis & Iron Mountain Southern Railway, and the Illinois Central. IC reached Thebes via a branchline from Carbondale, IL. Traffic never reached expectations and by the early 1930s (the exact date is unknown to me) the southernmost part of the branch had been abandoned. IC sold its interest in the SI&MBCo. to Missouri Pacific, which also took over the St.LIM&S Railway, and thus became majority owner of the Thebes bridge. Eventually the C&EI abandoned its line into Thebes and sold its interest in the bridge to the Cotton Belt. Of course, today Union Pacific owns both the MoPac and Cotton Belt. |

|

| Tod Riebow posted A car load of classic Corvettes. |

|

| Jeremy Plant posted Pre-Chessie on the B&O at Harpers Ferry: open auto racks, GP30 and F7. The good old days, from summer 1968. |

|

| Carl Venzke posted |

|

| Carl Venzke commented on his posting |

|

| Carl Venzke commented on his posting |

|

| Carl Venzke posted Loading or unloading some model Ts. Apparently there was some assembly required at the destination. |

|

| Mark Llanuza posted Its Nov 1975 westbound with brand new auto's passes through Griffith Ind with three E-units. Randy Crismore It's amazing how back in the day...very little vandalism occurred as compared to today. |

|

| Wayne Hudak commented on Mark's posting Oh, there was vandalism back in the day.The reason auto racks were eventually covered was due to a lot of vandalism and theft from autos. When the auto rack cars had no sides you could see none of the cars had hubcaps. Due to constant theft they were eventually shipped in the trunk of each car. Here's an example below. photo 3-17-77. |

Wayne Hudak Thanks for the update. I often wondered about the keys.

Joseph Tuch Santucci Wayne Hudak for a time they put them in the ash trays. Then the put them all into an envelope and hid them in or on one of the cars. In the 80’s they stared send the keys separately. Today they have the airbags disconnected. Those are hooked up at the dealerships.

Don Murray posted four photos with the comment: "I do not know where this is, They look like 1971 Chevy trucks."

Dennis DeBruler shared with the comment: "A testament to the strength of a good chaining job."

Mike Budde

I wonder if these were coming from Janesville. Someone on another group said this location was Alma, IL on the IC, from the name on the water tower. As others have mentioned, what an excellent job those guys did tying these trucks down to the train cars.

I wonder if these were coming from Janesville. Someone on another group said this location was Alma, IL on the IC, from the name on the water tower. As others have mentioned, what an excellent job those guys did tying these trucks down to the train cars. |

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Dustin Newton posted The new 73 Plymouths are here Steven Marcyk When autos came in more colors then shades of silver and white. |

Greg Bunce posted two photos with the comment: "Here's a couple of builders photos of GTW Automobile boxcars built by American Car and Foundry in 1921. Photos from the John W. Barriger Railroad Library."

|

| 1 |

|

| 2 |

|

| Peter Dudley shared New Hudson automobiles were being loaded into a New York Central System (post-1935) automobile boxcar, in this undated photograph. The Hudson plant was located along Detroit Terminal Railroad on Detroit's east side, near Conner and East Jefferson, I believe. J.L. Hudson was a partner in the company. |

|

| Peter Dudley posted New Ford Model T automobiles are shown being loaded onto Michigan Central Railroad (M.C.R.R.) "Automobile" boxcars, utilizing "a second shipping platform" alongside M.C.R.R.'s street-level Peninsular Spur industrial track, which ran behind Ford Motor Company's 1904 Piquette Avenue factory in Detroit MI. This photograph was shot some time between 1908 and 1910, when Model T production moved to Ford's new Highland Park plant. When all tracks in the area (including the Peninsula Spur) were elevated in 1911, new Piquette plant - owner E-M-F / Studebaker erected an elevated second-story loading platform (which still stands). Note the FORD logos on the boxcars. Raymond Storey posted Detroit circa 1909..Loading Model Ts. |

|

| Tory Marmaduke posted Brand new Chevy's.... looks to be 1956, being delivered to Sonoma, CA Don Butler Jo San Metz look at the turn signal lights. Definitely 56 Chevy Daniel C Carroll Jr. shared Rick F The could ship at least 4 if not 5 as the automobile boxcars had racks in them so they could be stacked over each other. If you look close at the picture you can see the end of a bumper above the mans head just showing near the top of the opening for the door. Dale Williams No rail dust on those cars ! Michael Haag Dale Williams Great point! It took me over 3 hours of hard work with a clay bar to get the rail dust off of my new Mustang in 2012. It appears that is beyond the usual dealer prep. Peter Dudley shared Evidently, double-door automobile boxcars were still-operational during the 1950s (when Lionel began producing three-rail O gauge versions). |

|

| Michael Catalano commented on Tory's post Here's how they were loaded inside, four to a boxcar. Hot, heavy manual labor to load and unload them. [Those are older model cars, and the older boxcars were probably shorter than the SP boxcar. I wonder if they got more than four in the SP boxcar. Stever Hart posted so THAT'S how they did it. Yes and based on the language my tender little ears heard they were a bitch to unload. |

|

| David Rochelle posted (source) This photo captures a batch of freshly assembled 1940 Fords leaving the Louisville plant in box cars to find their way to dealers. Ford used railways to ship cars long distances. Charles Aay Always loved the chevron tail lights on the 40s. Rick Tonet Black model closest to camera is a base model with only a single tail light. Richie Pointer I understand that only deluxes got dual rear tail lights on 40's. Jimy Takvingsson shared J Pete Hedgpeth: They moved in what was known as "Evans Device Cars"...high cube. Seres of chains and platforms to hoist the cars up to allow the lading to be "stacked". Sometimes the chains broke or sllipped. The results were not pretty. Arthur Mallette: 1940 Fords (Some comments show the "one and only PRR x-30" that was used to ship fire trucks.) Ray Oak: Hard to imagine everything went by box car at one time. Even grain was loaded into box cars Larry Behl: When I was 14 I helped at the home town elevator for a couple of weeks in early summer between de-tasseling and bailing hay to fill box cars with corn. We put wood planks on the inside and start filling as we worked inside to scoop the corn to the ends. When the car was half full we added more planks at the door to the point you had to crawl out when the car was filled. Not a fun job. Jim Manna: coopering a car, later they switched to cardboard with metal strapping. Vernon Davidson: That cardboard with the metal straps made into it was called "grain doors". I've nailed many of them in place to get a car ready for loading. |

|

| Jim Arvites posted View of new automobiles being unloaded at the Chicago, Burlington & Quincy Railroad freight house in Sandwich, Illinois in 1912. (Sandwich Historical Society) Dave Ladislas Sr. Friend of mine just sent me a pic,car on left looks like a Flanders Model 50-6. [The photographer was more interested in the cars than the boxcar. :-) Getting the cars out onto a narrow, steep ramp had to be even more tricky.] |

Eric S. Huffstutler posted four photos with the comment:

This is not new but still awesome to see. The Vert-A-Pac shipping system General Motors came up with to ship the Chevrolet Vega back in the 1970s. Developed along with Southern Pacific Railroad, GM was able to double the amount of Vega models it could ship by packing them into the unique storage cars vertically.

At the time, rail cars could fit 15 vehicles each, but Chevrolet was able to lower shipping costs by making it possible to ship 30 Vegas per rail car, in turn allowing the price of the Vega to remain as low as possible. Each rail car had 30 doors that would fold down so that a Vega could be strapped on, and then a forklift would come along and lift the door into place. All the cars were positioned nose down, and since they were shipped with all of their required fluids, certain aspects had to be designed specifically for this type of shipping, including an oil baffle in the engine, a special battery and even a repositioned windshield washer reservoir. Any other cars shipped in as an unusual way?

Craig Nicol I remember the original batteries for those cars had their cell caps at one edge of the battery so they wouldn't spill in transit. All the underhood reservoirs too.

Eric S. Huffstutler They made over 2-million of these cars between 1971-1977. Pinto was produced 3 years longer 1971-1980 and produced just over 3-million.

Emery Flatt The Ford Pinto was shipped the same way. [This comment was evidently wrong. But as proof that he was correct, he posts a photo of a standard covered autorack. And yet later in the comments he delights in pointing out someone's typo. He has more comments, and I think I now understand what an internet group "know it all" is.]

Todd Allen Typically new cars are filled with fluids for testing, then drained for shipping. They still do this today.

Steve Dolan I know from personal experience, Toyotas are shipped via rail with all fluids. They even start them and drive them off the rail car. Watched them unload many of them at Southeast Toyota Distributors.

Al Carpenter Ed Cole's folly. GMAD Lordestown could build 100 unit per hour. Sales were far less brisk. The freedom battery was perfected, true, but rural offloading occasionally involved guiding a fork lift arm through open windows to keep rail schedules. Repairs were extensive.

Eric S. Huffstutler More info... Vega’s engineers had to design a special engine oil baffle to prevent oil from entering the No. 1 cylinder of the car’s inline-four engine. Batteries had filler caps located high up on the rear edge of the case to prevent acid spills. The carburetor float bowl had a special tube that drained gasoline into the vapor canister during shipment, and the windshield washer bottle stood at a 45 degree angle. Plastic spacers were wedged between the powertrain and chassis to prevent damage to engine and transmission mounts. The wedges were removed when cars were unloaded.

John Levy I was there. Trust me, there was a high demand for this car, along with the Pinto. In 1974, they sold over 460,000 Vegas. There were a lot of very good features on the car, but it was also woefully inadequate in many ways. I had a brand new 73 and it drove and handled very well. Obviously there aren't many left because of the dreadful rust prevention on the car. The original aluminum block engine was poorly designed. The interior was very nice and dang it was rear wheel drive. Can you imagine a bargain priced rear wheel drive car in today's market?

George Bishopric Though the Vega’s die-cast aluminum engine had undergone some 6 million miles of development testing, serious reliability issues surfaced soon after the car’s release. A six-quart cooling system and small radiator proved barely sufficient to prevent overheating in warmer climates, and the aluminum engine block soon earned a reputation for distorting when hot. This frequently led to the piston rings scraping the silica used to harden cylinder walls, increasing oil consumption (though to be fair, valve stem seals were also a known source of oil consumption). In extreme overheating, the engine block’s distortion could be severe enough to compromise the head gasket, leading to coolant leaks and further destructive overheating.

Chevrolet took until 1976 to resolve issues with the Vega’s 2.3-liter four-cylinder engine, and by then even a serious marketing effort to promote the new “Dura-Built 140” engine proved to be too little, too late. The new engine improved coolant flow through the block; used a revised head gasket and water pump; added revised valve guide seals; and changed the thermostat, but not even an increased five-year, 60,000-mile warranty was enough to restore consumer confidence. Sales in 1975 totaled just more than 206,000 units, and fell even further, to less than 161,000 units, following the release of the Dura-Built 140 engine in 1976. In 1977, the Vega’s final year of production, only 78,402 models found their way into consumer driveways.

George Bishopric I bought one when I was 18. The things I liked about it then, I still like about it.

For its time, it was a relatively comfortable small car. It handled very well, and until it began to fall apart, it was quite competitive with other small cars which you must remember we were remarkably more tinny, noisy and cramped than any small car today

The car had a appalling quality, however. The plastics used in the interior would be rejected for Walmart for use in a dishwashing rack. The carpet was basically lint, pulled from an industrial clothes dryer. The inner fenders were deleted to save money, along with a glove box

The cars began rusting, almost before they left the show room. My windshield and rear window had to be removed for rust repair within six months of purchase. The tires had to be replaced at 16,000 miles. Back in the day, that was outrageous, and these were not high-performance tires by any stretch.

George Bishopric The motor's issues were best symbolized by the oil filler cap: Basically, a rubber bottle stopper, that could only be removed with difficulty, which was a problem in such an oil thirsty motor. My engine blew a head gasket at 18,000 miles on a cool Sunday morning. By the time I traded the car in, it could not go more than 40 mph with passengers in it.

Todd Allen I remember taking a head off one of these Vegas- the bolt was so seized I used a water pipe for a hot water heater pressure relief valve drain over the rachet (about a 4 foot leverage arm) and broke two sockets with two guys working on it. Had to buy an industrial grade impact socket before that sucker woud budge and my 4 foot breaker bar.. Blown head gasket of course.

George Bishopric Patrick Mullen GM basically handed the small car market to Toyota at that point. Had GM gone with the "premium small car" concept, and not slashed quality to meet unrealistic price targets, they would have met the challenge of import competition. A massive unforced error.

George Bishopric "Contrary to popular belief, GM did rust proof the cars, but its design allowed for air pockets to develop between the front fenders, cowl, and firewall during the rustproofing process, leaving the steel in those areas dangerously unprotected. Yet while all these defects were known to company brass, the Vega debuted on September 10, 1970, and just like GM hoped...." http://www.cheatsheet.com/.../why-the-chevy-vega-set.../...

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Eric commented on his post |

|

| Eric commented on his post [Al Carpenter elaborated that there was not enough room by the sidings in rural areas to lower the ramps all the way. That is why they used forklifts to unload cars.] |

|

| Eric commented on his post The cars were hanging on the railroad car doors by four cast iron hooks attached to the chassis. |

|

| Eric commented on his post Here are stacks showing Cadillac cars in them. [Eric posted this as part of a discussion of vertical clearances and weather or not the Vet-A-Pac cars could go all the way to the East Coast. I was not aware of this form of auto transportation.] |

There is a wealth of information about autos in boxcars in the comments for this posting. (I verified with an Incognito Window that you don't have to be a member of the group to read the comments, but you do have to be a member of Facebook.)

The following information came from the comments by Bob Lalich and others on a post asking about this facility with a figure-8 track. Note that the "X" of the "8" appears to be grade separated. According to topo maps, it was built between 1929 and this 1938 aerial photo. My current theory is that the track was used for accelerated testing of the trucks turning in a new, possibly interurban, car design.

Bob Lalich It was Evans in later years. Before that I think it was US Railway Equipment, and possibly Wells & French before that.

|

| 1938 Aerial Photo from ILHAP |

|

| Google Earth, Mar 30, 2002 |

|

Daniel O'Hearn Looks like we are not the first people to talk about this particular railroad anomaly. Here is a question someone asked on a discussion board several years ago (if interested, here’s the link to that discussion board here: http://cs.trains.com/trn/f/111/t/177956.aspx?pi332=2). A Mr. Paul North had the following to say about it: |

Information from https://www.midcontinent.org/rollingstock/list/listhome.htm doesn't include the change from US Railway Equipment Manufacturing to Evans nor that French & Wells was the precursor to US Railway.

|

| W |

|

| U |

|

| E |

Paul Musselman commented that a Google search with the keywords: "Evans automobile boxcars" offers several photos. Looking at the photo results, Kalmbach covers this topic in their Railroading & The Automobile Industry book. And core77 has four photos from LIFE on the subject.

|

| Dennis DeBruler commented on the post I pursued some links from your Google search and found: "Founded as U.S. Railway Equipment, or U.S. Railway Manufacturing, the name was changed to Evans Railcar Manufacturing in 1964. Evans Products Freight Cars built in the 1960's, 1970's, and 1980's were plentiful in the 1990's and many EP Freight Cars are still around. SIECO became one of their subsidiaries. Evans was purchased by GE Transportation sometime in the 1980s and transformed into a maintenance division." https://trovestar.com/generic/zoom.php?id=142619 That page also explains: "With the Per Diem rules implemented by the US government to encourage railroads to purchase more boxcars, boxcar manufacturing roared into gear in the 1970s. Every major manufacturer cranked out 50 foot boxcars to satisfy the demand. Evans was no exception. Empowered by its acquisition of United States Railway Equipment (USRE), Evans-USRE boxcars became ubiquitous during the IPD boxcar boom of the 1970s. With modern upgrades such as box-corrugated, non-terminating ends, Stanray X-panel overhanging roof, and riveted car sides near the end posts, the Evans-USRE 5277 is a classic boxcar of the IPD era." |

Bob Lalich Daniel O'Hearn - that thread from Trains discussion forum has a good tidbit of info. The Blue Island site was once the Mather Stock Car Co, which was merged into North American Car Co. at some point. The 1956 directory of industries lists a site for North American at 135th St in Blue Island.

Dwayne Weber posted two photos with the comment: "Found some info on something NYC either explored or declined. Anything out there about the possible color of the flat or carrier?"

Kim Powell Guess there was a prototype for Lionel's#6414 Evans auto loader.

[Evans evidently developed this design as a transition to the autoracks we see today.]

Richard Roberts shared

Greg Worobey I had a Lionel flat was black and carrier red.

Stuart Thomson I have the original press release book from Evans but it is in black and white. I am sure the flat was black. Not sure on the rack. Evans paid for the Lionel tooling. Evans designed the rack to permit end loading or side loading off to a dock. Unfortunately they never tried using a PRR 75' flat car or the new 85' trailer flat car. to load more cars. Problem was autos at that time were very high and a tri-level was not possible, thus not enough revenue. Plus the rack was very heavy and expensive. However in 1960, auto companies introduced unit body construction which lowered the car height by about a foot. Then Frisco and ATSF could make tri-levels for their high clearances. In 1961 the eastern railroads introduced elevator racks that lowered the overall height by 2'. It took three more years to open up clearances in the east for standard tri-levels with fixed decks ( the "B" deck was hinged at the ends ) on low level flats that also had EOC couplers. Those elevator racks only lasted five years and were scrapped or rebuilt.

Stuart Thomson That superstructure with the chain drive to raise and lower decks really added to the cost plus having the heavy bridge construction to permit side loading also added cost to the rack. Too bad the concept of just end loading of autos was still five years away. Also at the time box cars with autos would go to area sidings nearest the dealer and off load. Sometimes the box car would make two stops. Unlike shipping cars to a huge off load yard of today.

|

| 1 |

|

| 2 |

Another transition solution.

|

| David Mackey posted Larry Higgs 1959 Plymouth’s Imperials Dodges and I think a hiding DeSoto. Tod Riebow shared Dan Bohannon Looks like Lindenwood yard! Mike Budde Dan Bohannon it definitely is. That’s the old Arsenal Street bridge. Heading east from the brand new Fenton Chrysler Plant built in 1959. Those Plymouths, Dodges and Chryslers were their first product. [I have no idea which state, let alone town, Lindenwood Yard is in.] |

|

| Randy Alan posted I believe these entire trailers were attached to flat cars. Early multi-modal, I guess. |

Higher resolution copies of the new photos displayed above.

|

| Higher Res |

|

| Higher Res |

|

| <foreign language> posted Fernando Muller shared James Williams Those carriers were sold to the Auto Train corp Vernon Davidson Those box cars were later seen with those end doors welded shut and a plywood bulkhead built inside the ends. They then just hauled general merchandise. Shortly after this time of 1957, TTX Corp. started building 89 foot flat cars and the railroads added the double and triple deck auto racks for easier handling of new autos. TTX Corp. was actually an "all" U S railroad owned corporation. |

|

| Jeffrey Wincek posted Railroading when it was cool. Don McLean Been there and did that.We never had radios and all signals were given by hand and the guy on top of the cars relayed them to the engineman.There used to be two men in the cab of the locomotive.The second man was called the fireman.I guess a draw back to steam when he would keep the fire going to keep the steam up.They used coal and then went to buncer "c" oil.Then came the diesel and the fireman was eventually fased out.He was kept on as a more or less safety feature. When Walkie Talkies came into play and the signals were relayed directly to the engineman ,the man on the roof of the cars and the fireman were no longer necessary.We used kerosene lanterns at night. JR Sampson About 1960-61 from the looks of the cars on the autorack. Don McLean It was in the early sixties that the radios came into operation.They made a brakeman's job a lot safer and a bit easier.It put three men on the ground. JR Sampson Don McLean I was passing signals from cartops and over in the farmers field still in the late 70s. Kenny Backes they'd fire your ass if they ever caught you passing signals from on top a box car even when I hired out in the 70's. Michael Schmidt Kenny Backes We did in the yards on the Milwaukee Road. Did it till they outlawed the running boards. Arthur Houston RR when roof walks were in use were the most dangerous place in the world to work. Casualties would go past a 1000 a year. Richard Long Never had the opportunity of riding on top of the cars. But was able to enjoy dropping cars and kicking cars plus getting on and off moving equipment. Don McLean Before the radios when we came out of a siding we had to line the switch back and run to catch the caboose.If the engineman underestimated his train the conductor had to put it into emergency or you got left behind. Started of working with no CTC.Ran on train orders only.You had to know your Rule book then. Tom Lyman "Going High" we did it well into the 70's in all kind of weather snow, rain, daylight, dark, walked from car to car as needed. Andrew Van Wagnen My dad said that some times the only time feet hit the ground was beans, coffee and going home. Tim Jantzen Those were not 'the good ol days' Most of you are too young to remember railroad men couldn't even get life insurance. Falling off the roofs were common and so were fatalities. It might look cool to run across the roof but it's anything but. The tail end crew breathed in asbestos and who knows what else. Hours were awful and so was the pay. Enjoy what you got because a lot of people died before safety even became a word. Before the 80's most conductors died before they even collected their first retirement check because of cancer and hoggers were deaf. Kenny Backes truer words havent been spoken on here....good ole asbestos brake shoes. Ralph Herman Hired out mid 60s retired in 08 we passed signals from the top of cars. There was running boards on the top eventually were removed , most boxcars had high hand brakes than . Robert Carlyle Lewis In the days before portable radios this was a common way to pass signals when working on curves. Someone would be on the ladder next to the locomotive and pass the signals to the engineer. You just didn’t want to ride the end of the last car since slack and/or a hard joint could knock you off. Wayne Ladd Back when brakemen were actually brakemen! Michael Schmidt I hated fixing the running boards. I loved it when we started cutting them off all the box cars for safety and repair reasons.. Dave Stelly I have walked a mile on the top of grain hopper cars. Easy. Yes it was moving about 20. |

Jason Boche shared : a video of the top of some autoracks being "scraped off."

Some dispatchers getting fired!

And the crew. The crew will always be the scapegoats. They know the height restrictions on their line and know the height of each car in their consist. Three layers of redundancy.

The dispatcher had to override the system to be able to put them on that subdivision so that’s gonna hurt!

There is something I am curious about.

In the beginning there is one roof that is already crumpled before the train hits the overpass.

Thoughts?

Ron

Author

the majority of this video is the second shove move. There must have been an initial shove move that did that damage and it went undetected.

I’m pretty sure this happened in Memphis on the Cn I work for them and on this territory . There is a bulletin saying to take nothing but your indrusty cars into Valero and they didn’t get the memo.

Been there, seen that......they ripped the tops off of racks several times in Cicero at the BRC Bridge several times....... [Some of the tracks are deep enough, some are not. If the dispatcher puts the train on the wrong track, there is trouble.]

No comments:

Post a Comment